How to ensure 99.9% uninterrupted production and increase profits

General Overview

-

Reduction of critical component inventory requests from several days to 24 hours

-

Selection of replacement deliveries from 1-2 weeks to a few days

-

Reduction of production breakdown risk from 2% to 0.1

Challenge

As a manufacturer of premium cars, we are continuously working to improve and develop our own products. During the production from time to time the stock of different material for production is running out of stock. To avoid the interruption of production lines the production contacts the purchasing department by phone or email to request ad hoc orders. The purchasing department receives manual inquiries by email from suppliers, and the processes is then only be tracked manually from members of the procurement department. The challenge was the manual inquiry and procurement of parts with critical stock quantities, resulting in worst case in an imminent production standstill. The processing times for inquiries were significantly too long, and there was a high risk of production downtime.

SAP, as the core platform for procurement management, could not implement the necessary processes.

Action

To reduce the risk of production interruption the following goals were defined

-

Shortening the procurement of critical purchasing parts

-

Processing, including contacting the manufacturer/distributor/broker

-

Integrated automated escalation in case of missed deadlines

-

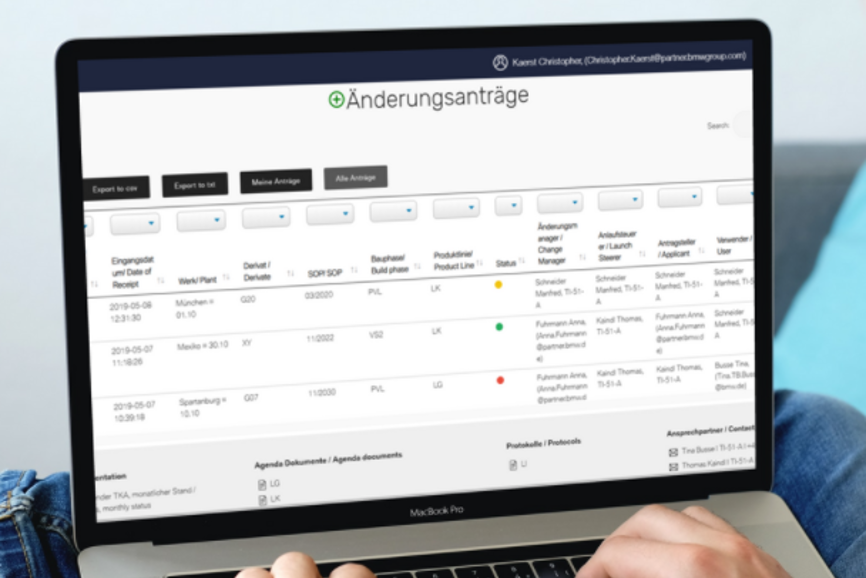

Support of multi-party discussions

As solution the implementation of a specialised ticket system to track inquiries was implemented. In the solution an online view of order processing from different positions is possible. A mapping of distributed requests to several manufacturers with subsequent consolidation is the core process. E-mail for notification with a simple deep link mechanism into the process was developed.

During the first project iteration a solution was implemented with Microsoft 365 as pilot application in 3 months.

Result

The following benefits could be achieved:

-

Reduction of critical component inventory requests from several days to 24 hours

-

Selection of replacement deliveries from 1-2 weeks to a few days

-

Reduction of production breakdown risk from 2% to 0.1

Perspective

The application will be extended in next project iterations to consider the implementation of further requirements. The communication with suppliers and process integration will lead to faster response times on the same working day and will further be improved with additional extensions.

Used Technologies

-

Power Automate

-

SharePoint

-

Teams

-

bloola factory framework

You May Also Like

These Related Stories

Successful Implementation of an AI-Based E-Learning Assistant in Professional Development

30% more attractive products with an intelligent feedback process